An Agricultural Sprayer Pump is not just a supporting component in spraying equipment. It directly influences application accuracy, spray stability, and chemical handling. In field operations, uneven pressure or incompatible materials often result in clogged nozzles, uneven droplet size, and wasted chemicals. These are common frustrations that growers and equipment operators face season after season.

From a factory perspective, pump selection is usually where performance differences begin. A well-matched pump helps maintain steady output across the boom, even when operating conditions change. This stability becomes especially important when working with fertilizers, herbicides, or insecticides that require controlled application rates.

Why Diaphragm Pumps Are Widely Used for Spraying

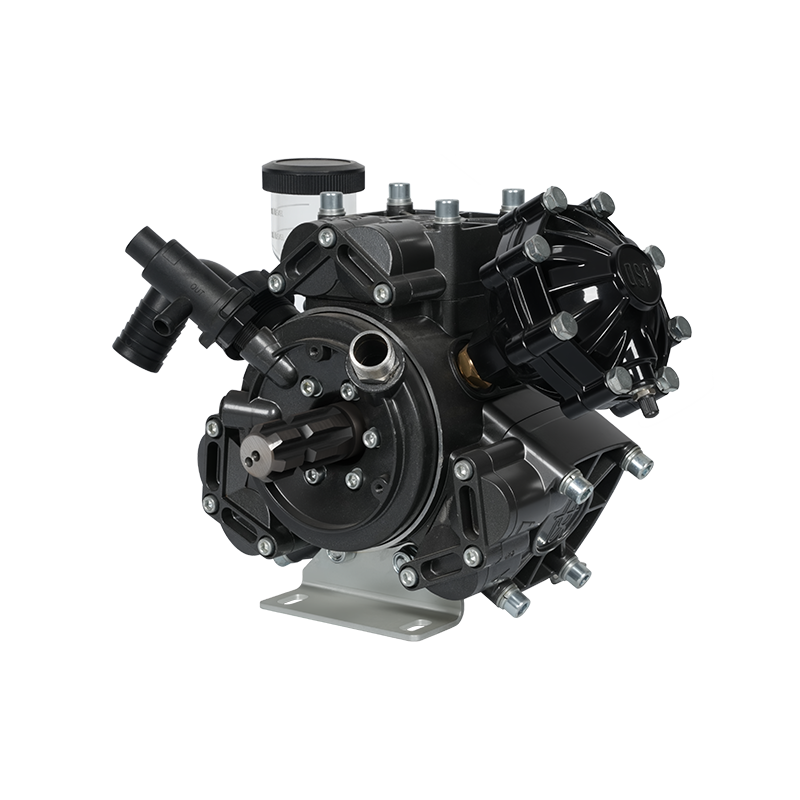

Diaphragm pump designs, especially piston-diaphragm structures, are widely adopted in agricultural spraying systems. One reason is chemical compatibility. These pumps are commonly built using polypropylene housings, EPDM or PTFE diaphragms, and chemical-resistant valves. Such material combinations handle a wide range of agricultural liquids without rapid degradation.

Another practical benefit is dry-run tolerance for short periods. During tank refilling or when suction lines briefly lose liquid, a diaphragm pump is less likely to suffer immediate damage compared with other pump types. This characteristic reduces unexpected downtime in daily field work.

Self-priming ability also simplifies installation. A diaphragm Agricultural Sprayer Pump can lift liquid from a tank positioned below the pump inlet, allowing more flexible equipment layouts. At the same time, it can generate pressure suitable for operating multiple nozzles across a wide boom.

Flow Rate and Pressure: Matching the Real Application

Flow rate and pressure are often misunderstood. The required flow rate depends on boom width, travel speed, and the target application volume. By calculating total nozzle output, operators can determine how much liquid the pump must deliver per minute.

Pressure requirements are tied closely to nozzle design. Many agricultural spraying systems operate within a range of approximately 40 to 150 PSI. The pump must maintain this pressure consistently while delivering the needed flow. Selecting a pump with some margin above calculated needs helps compensate for wear over time and maintains stable spraying performance.

Chemical Compatibility and Material Selection

Chemical compatibility directly affects pump service life. When evaluating an Agricultural Sprayer Pump Manufacturer, attention should be given to diaphragm materials and wetted components. EPDM diaphragms are commonly used for many fertilizers and herbicides due to balanced performance and cost. For more aggressive formulations, PTFE diaphragms are often chosen because of their resistance profile.

Housing and valve materials also matter. Polypropylene is widely used due to its resistance to corrosion and broad chemical tolerance. Stainless steel may be selected in specific cases where structural strength or chemical exposure requires it. Reviewing chemical resistance charts from the manufacturer helps avoid premature seal or diaphragm failure.

Durability and Maintenance in Daily Use

One advantage of diaphragm pump construction is the separation between the hydraulic oil and the pumped chemical. This design protects internal components from direct exposure to abrasive or corrosive fluids. Over time, diaphragms and valves will wear, but replacement procedures are generally straightforward and can often be done without specialized tools.

This maintenance approach supports predictable operating costs and reduces extended equipment downtime. For many operators, the ability to service wear parts in the field is just as important as initial pump performance.

EN

EN  English

English 中文简体

中文简体 русский

русский