Why Inlet And Outlet Water Filters Are Non-Negotiable for Agricultural Sprayers

Agricultural spraying systems rely on the precise delivery of pesticides, fertilizers, and other crop protection solutions to target areas. However, spray solutions rarely arrive pure: they often contain hidden impurities like dirt, debris, sand, or even residual particles from previous applications. Without proper filtration, these contaminants can wreak havoc on the entire system—starting with the vulnerable part: the spray nozzles. “Nozzle clogging is one of the top frustrations for farmers using sprayers. “A single clogged nozzle disrupts the uniformity of spraying, uneven coverage. Some areas get too much solution, risking crop damage, while others get too little, leaving plants unprotected from pests or nutrient deficiencies. This not only wastes resources but also hits farmers’ bottom lines hard.” This is where inlet and outlet water filters step in. Their primary function is to trap and remove these harmful impurities before they reach the nozzles. Inlet filters, installed at the point where water or solution enters the sprayer tank, catch larger debris early in the process. Outlet filters, positioned just before the solution flows to the nozzles, provide a final line of defense, ensuring only clean, particle-free liquid is distributed. Together, they create a two-layer protection system that keeps sprayers running at peak efficiency.

Choosing the Right Inlet And Outlet Water Filters for Your Agricultural Needs

Not all inlet and outlet water filters are created equal. To maximize their benefits, farmers should consider several factors when selecting filters for their sprayers:

Filter Material: Look for durable materials like stainless steel or high-grade plastic that can withstand harsh agricultural chemicals and weather conditions.

Mesh Size: The mesh size determines the size of particles the filter can trap. For agricultural applications, a 50-100 micron mesh is ideal—small enough to catch harmful debris but large enough to avoid frequent clogging.

Compatibility: Ensure the filter is compatible with your sprayer’s make and model. Ill-fitting filters can leak or fail to function properly.

Ease of Maintenance: Opt for filters that are easy to clean or replace. Farmers with busy schedules need filters that don’t require excessive downtime.

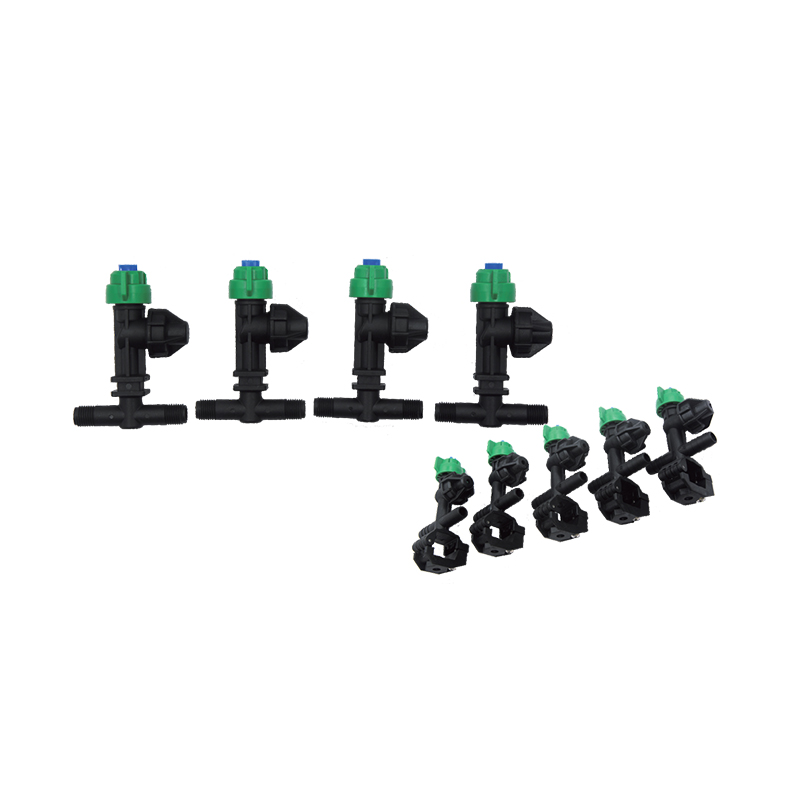

How to Choose Inlet and Outlet Valves?

Selecting suitable inlet and outlet valves is important for ensuring stable performance in water delivery systems, sprayers, pumps, and household irrigation setups. Because valves regulate the flow of water and maintain reliable operation, choosing the correct type involves evaluating system requirements, material compatibility, pressure range, and long-term maintenance expectations.

The factor to consider is system flow requirements. Inlet valves regulate the flow of water entering a pump or sprayer, while outlet valves release water into the system or toward the nozzle assembly. Choosing valves with appropriate flow capacity prevents bottlenecks. Oversized valves may reduce fine control, whereas undersized valves can restrict performance. Manufacturers often specify flow coefficients (Cv values) that indicate how much water passes through at a certain pressure.

Another important factor is pressure rating. Inlet valves must withstand suction forces and prevent cavitation, while outlet valves manage pressure generated by the pump or water source. Users should confirm operating pressure and ensure the selected valve is rated with a comfortable margin above expected working conditions. This helps maintain efficiency and reduces strain on valve seals and internal components.

Material selection also plays a major role. Common materials include plastic (polypropylene or nylon), brass, and stainless steel. Plastic valves are lightweight and corrosion-resistant, suitable for general garden and low-pressure systems. Brass valves offer improved durability, making them appropriate for more demanding applications. Stainless steel provides high corrosion resistance and strength, especially in environments where chemicals or fertilizers are used.

Users should consider valve design. Ball valves provide simple on/off control, while diaphragm valves offer smoother regulation suited for sprayers and irrigation systems. Check valves at inlets prevent backflow, helping protect pumps and maintain prime. At outlets, adjustable flow valves offer finer control for nozzles and spray assemblies. Each design supports different performance goals, so alignment with the system’s function is essential.

Maintenance and compatibility should not be overlooked. Valves with removable caps or accessible internal parts allow easier cleaning. Systems using fertilizers or chemical solutions may benefit from valves with reinforced seals and gaskets. Compatibility with hose size, thread type, and existing fittings ensures smooth installation and reliable performance.

What Are the Different Types of Garden Hose Nozzle Sprayer Filters, and What Are Their Differences?

Garden hose nozzle sprayer filters help protect nozzles and sprayers from debris, mineral particles, and sediment that may reduce performance or cause clogging. Because outdoor water sources can vary in quality, filters provide an added layer of protection that supports consistent watering or spraying. Several types of filters are commonly used, and each offers distinct characteristics suited for different tasks.

One widely used type is the mesh screen filter, which contains a fine metal or plastic mesh that captures larger particles before they reach the nozzle. Mesh filters are simple, affordable, and easy to clean. They are suitable for everyday garden hose use where debris levels are moderate.

Another common option is the inline cartridge filter, which provides a larger filtration surface and finer particle retention. Cartridge filters are ideal for applications requiring cleaner water, such as applying liquid fertilizers through hose-end sprayers. They trap smaller particles and often operate for longer periods before needing cleaning or replacement.

For environments with heavy sediment, the sediment trap filter is particularly useful. These filters use a conical chamber or sediment reservoir where heavier particles settle before reaching the main filter element. Sediment trap filters extend the life of the sprayer and reduce maintenance time.

A more specialized option is the activated carbon filter, used primarily when odor or slight chemical contamination is a concern. While less common for garden sprayers, they are sometimes used when water clarity or sensitivity of plants requires improved filtration quality.

Pressure-regulating filters combine filtration with downstream pressure stabilization. These are used in drip irrigation systems or sprayers where specific pressure ranges must be maintained.

Comparison of Garden Hose Nozzle Sprayer Filters

|

Filter Type |

Main Function |

Filtration Strength |

Maintenance Frequency |

Typical Applications |

|

Mesh Screen Filter |

Captures large particles using metal/plastic mesh |

Medium |

Low to moderate |

General garden watering, hose nozzles |

|

Inline Cartridge Filter |

Provides finer filtration with replaceable cartridge |

High |

Moderate |

Hose-end sprayers, fertilizer application |

|

Sediment Trap Filter |

Separates heavier debris before filtration |

Medium to high |

Low |

Areas with sandy or sediment-rich water |

|

Activated Carbon Filter |

Reduces odor and improves water clarity |

Medium |

Moderate |

Sensitive plant care, specialty spraying |

|

Pressure-Regulating Filter |

Filters water while stabilizing pressure |

Medium |

Low |

Drip irrigation, controlled-pressure sprayers |

When deciding which filter to select, users should consider water quality, sprayer type, and maintenance ability. Mesh filters work well for general use, while cartridge and sediment trap filters provide protection when water contains fine debris or mineral buildup. Activated carbon filters offer added refinement but are typically unnecessary for standard gardening tasks. Pressure-regulating filters are used when precise water delivery is essential.

Choosing the right sprayer filter not only protects equipment but also improves spray consistency and supports longer service life. Regular cleaning ensures performance, regardless of filter type.

EN

EN  English

English 中文简体

中文简体 русский

русский