Beyond uniform spraying, flow dividers deliver multiple tangible benefits that address farmers’ pressing concerns.

Boost Operational Efficiency

By automating flow control, flow dividers eliminate the need for frequent manual adjustments. Dr. Miller notes, “Farmers using sprayers equipped with flow dividers report a 25%+ increase in operational efficiency—they cover more land in less time, and rework (due to uneven spraying) is nearly eliminated.” This is especially critical during busy seasons (like pre-harvest pest control), when time is a valuable resource.

Ensure Human and Machine Safety

The intelligent detection function of flow dividers acts as a “safety guard.” If a pipeline blockage or hydraulic failure is detected, the system automatically alerts the operator or shuts down the sprayer to prevent equipment damage or chemical leaks. “Prior to flow dividers, operators often didn’t notice issues until damage occurred. Now, proactive safety measures reduce accident risks for both workers and machines.”

Reduce Pesticide Waste and Environmental Pollution

Uneven spraying is a major cause of pesticide waste—excess chemicals seep into soil or waterways, harming ecosystems. Flow dividers ensure precise liquid delivery, cutting pesticide waste by 15%-20% on average. This not only lowers farmers’ input costs but also aligns with global sustainability goals, as it minimizes the environmental footprint of agricultural operations.

How to Choose the Right Flow Divider

Not all flow dividers are suitable for every self-propelled sprayer. To maximize their benefits, farmers should consider the following factors:

1. Compatibility with Sprayer Models

Flow dividers must match the sprayer’s horsepower, tank capacity, and pipeline design. An ill-fitting unit will fail to deliver performance—for example, a low-power flow divider can’t handle the flow demands of a large-scale sprayer.

2. Technical Configuration

Prioritize units with advanced intelligent detection (e.g., real-time pressure monitoring) and flexible hydraulic adjustment (to adapt to different crops). “Electronic modules that integrate with GPS or farm management systems are also a plus,” Dr. Miller suggests, “as they enable data-driven spraying decisions.”

3. Durability

Agricultural environments are harsh (dust, chemicals, temperatures). Choose flow dividers made of corrosion-resistant materials (like stainless steel) to ensure long-term use. “A durable flow divider can last 5-8 years with proper maintenance, making it a cost-effective investment.”

Flow Dividers—A Must-Have for Modern Agriculture

As precision agriculture continues to evolve, flow dividers have emerged as a non-negotiable component for self-propelled sprayers. Their ability to integrate electronics, hydraulics, and intelligent detection delivers uniform spraying, higher efficiency, and safer operations—all while reducing environmental impact. For farmers looking to stay competitive and sustainable, investing in a high-quality flow divider is not just a choice, but a strategic decision for long-term crop success.

What are the Characteristics and Functions of an Agricultural Aluminum 4-Way Splitter?

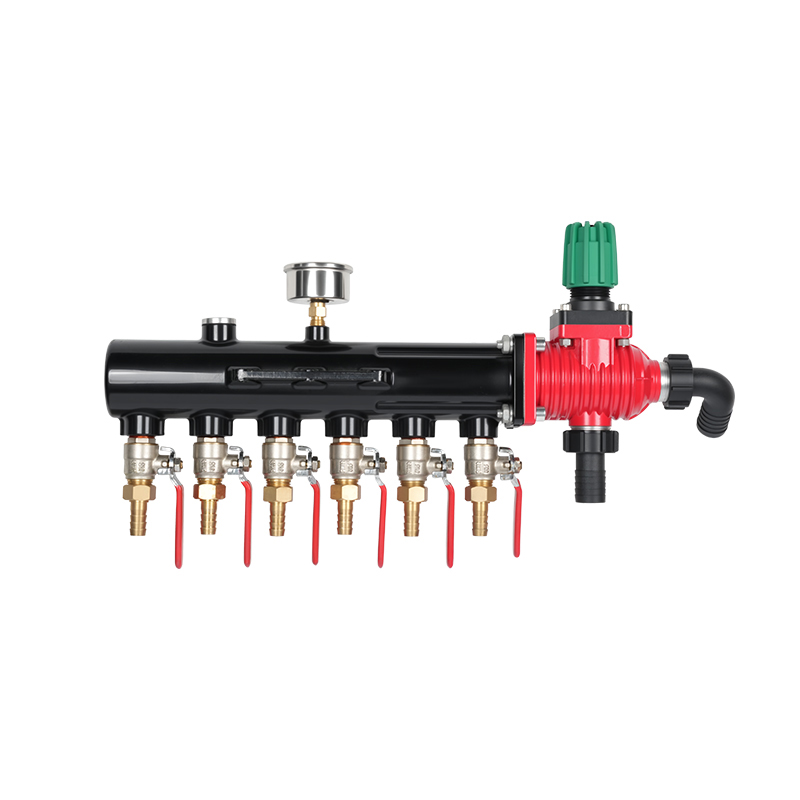

Within the intricate network of modern agricultural sprayers, the efficient and organized distribution of chemicals is paramount. One component that plays a critical role in this process, particularly for complex spraying systems, is the agricultural aluminum 4-way splitter. This fitting serves as a central manifold, designed to divide a single liquid input from the main pump into four separate, simultaneous output lines. Its design and construction incorporate specific characteristics that make it well-suited for the demanding environment of farm operations.

The prominent characteristic of this component is its material composition. Manufactured from aluminum alloy, the splitter offers a favorable balance between strength, corrosion resistance, and weight. Aluminum provides sufficient structural integrity to withstand the typical operating pressures of agricultural sprayers, which often range from 40 to 150 PSI, while being significantly lighter than a comparable steel fitting. This corrosion resistance is crucial for longevity, as the unit will be consistently exposed to a variety of agricultural chemicals, fertilizers, and weather conditions. While not impervious to all chemicals, aluminum generally holds up well against many common solutions, though compatibility should always be verified for specific chemicals in use.

The design of a 4-way splitter is focused on functionality and durability. It typically features one large inlet port, designed to connect to the main supply line from the pump, and four individual outlet ports. A key feature on many models is the inclusion of individual ball valves on each outlet. These valves allow an operator to manually open or close the flow to any of the four branches without affecting the others. This provides a high degree of control, enabling tasks such as isolating a single section of a spray boom for maintenance or repair while the rest of the system remains active, or configuring the sprayer for different boom widths. The internal passages are designed to minimize flow restriction and pressure drop, ensuring that each branch receives a consistent supply. The robust construction often includes reinforced mounting points, allowing the splitter to be securely fixed to the sprayer frame, reducing stress on the hoses and connections from vibration and movement during field operation.

What Types of Pressure Control Regulators Are Available?

Pressure control regulators are indispensable components in fluid systems, tasked with maintaining a stable, predetermined pressure downstream of the device, regardless of fluctuations in flow demand or upstream supply pressure. The selection of an appropriate regulator is dependent on the specific requirements of the application, including the desired level of control accuracy, the nature of the fluid, and the operating environment. Available types can be broadly categorized by their fundamental operating principle and design.

Direct-Operated Regulators

Direct-operated regulators, often referred to as simple pressure-reducing valves, are the common and economical type. They function through a self-contained mechanism where the downstream pressure acts directly on a diaphragm or piston, which is opposed by an adjustable spring. If the downstream pressure drops, the spring force opens the valve to allow more flow, thereby increasing the pressure back to the set point. Conversely, if the downstream pressure rises, the diaphragm or piston moves to restrict the flow. Their characteristics include simplicity, compact size, and cost-effectiveness. However, they exhibit a phenomenon known as "droop" or proportional drop, where the regulated pressure decreases slightly as flow increases. This makes them suitable for applications where precise pressure control is not critical, such as in general water service, pneumatic tool supply, and some agricultural sprayers where minor pressure variations are acceptable.

Pilot-Operated Regulators

For applications demanding more precise and stable pressure control under varying flow conditions, pilot-operated regulators are the preferred choice. These devices utilize a two-stage design. A small, internal "pilot" regulator controls a small flow of the medium, which is then used to load a diaphragm or piston that operates the main valve. This amplified pilot signal provides the force needed to open and close the large main valve with high sensitivity. The key advantage of this design is its accuracy; it minimizes droop and maintains a very consistent downstream pressure even with significant changes in flow rate. The trade-offs are a larger physical size, higher initial cost, and a potential for being more susceptible to contamination from dirty fluids due to the small orifices in the pilot stage. They are typically used in industrial processes, steam distribution, and irrigation systems where precise pressure management is necessary for system performance.

Specialized Function Regulators

Beyond the standard reducing regulators, several specialized types are designed for specific functions. Back-pressure regulators are installed on the outlet of a system and are designed to maintain a set upstream pressure by opening to relieve excess pressure when the inlet pressure exceeds the set point. They are essential for controlling pressure in vessels, reactors, and chromatography columns. Relief valves are safety devices that open fully at a predetermined pressure to prevent system overpressure and protect equipment. Electro-pneumatic regulators use an electrical signal (e.g., 4-20 mA or 0-10 VDC) to control the output pressure proportionally, allowing for remote and automated pressure adjustments from a control system, which is invaluable in automation and complex process control loops. Understanding these distinct types allows for an informed selection based on the specific control, accuracy, and safety needs of the application.

EN

EN  English

English 中文简体

中文简体 русский

русский