In the chain of precision agricultural equipment, from flow dividers controlling pipelines to final pesticide delivery, Nozzles stand as the "last mile" core component. Together with the nozzle body (the part that supports, secures, and delivers pesticide solution to each nozzle), they form the sprayer’s "terminal execution system." It is this system that directly translates the sprayer’s operational design into tangible results—through the nozzle’s sophisticated internal structure, high-pressure pesticide solution is broken into countless fine droplets, while the nozzle body ensures stable delivery. Their coordination directly determines atomization quality, droplet distribution, and spraying accuracy, all of which are critical to pesticide utilization and ensuring effective pest control.

Why Nozzles & Nozzle Bodies Are the "Make-or-Break" of Spraying

For farmers, the ultimate goal of using a sprayer is to ensure that every drop of pesticide acts on target pests or crops. However, this depends entirely on the performance of the nozzle and nozzle body.

If the flow divider is the ‘brain’ of the sprayer, then the nozzle and nozzle body are its ‘hands’ that directly deliver results. A well-designed nozzle can turn high-pressure solution into uniform, fine droplets that adhere tightly to crop leaves—avoiding large droplets that roll off or drift away. Meanwhile, a stable nozzle body ensures that each nozzle receives a consistent solution supply, preventing uneven distribution caused by loose connections or blocked delivery channels.”

Poor performance of either component can serious inefficiencies. For example, a nozzle with a worn internal structure may produce irregular droplets: some areas receive excessive pesticide (causing crop burn), while others get too little (leaving pests unchecked). A faulty nozzle body, on the other hand, may cause solution leakage or uneven pressure, resulting in patchy spraying that wastes pesticides and undermines pest control efforts.

Core Advantages of High-Quality Nozzles: Efficiency, Efficacy, and Sustainability

1. Improve Pesticide Utilization

The sophisticated internal structure of premium nozzles ensures that a high-pressure solution is atomized into droplets of size (usually 100-300 microns for crops). These droplets strike and adhere to crop surfaces without bouncing or drifting—reducing pesticide loss to soil or water by 20%-30% compared to low-quality nozzles. “This means farmers can use less pesticide to achieve the same control effect, cutting input costs while reducing environmental impact.”

2. Ensure Uniform Pest Control

By producing consistent droplet size and distribution, high-quality nozzles eliminate “spray gaps” or “over-spray zones.” For example, in wheat fields, uniform droplets can cover both the upper leaves and lower stems, targeting hidden pests like aphids. “Farmers using premium nozzles report a 15%-25% higher pest control rate, as no area is left unprotected.”

3. Adapt to Diverse Agricultural Scenarios

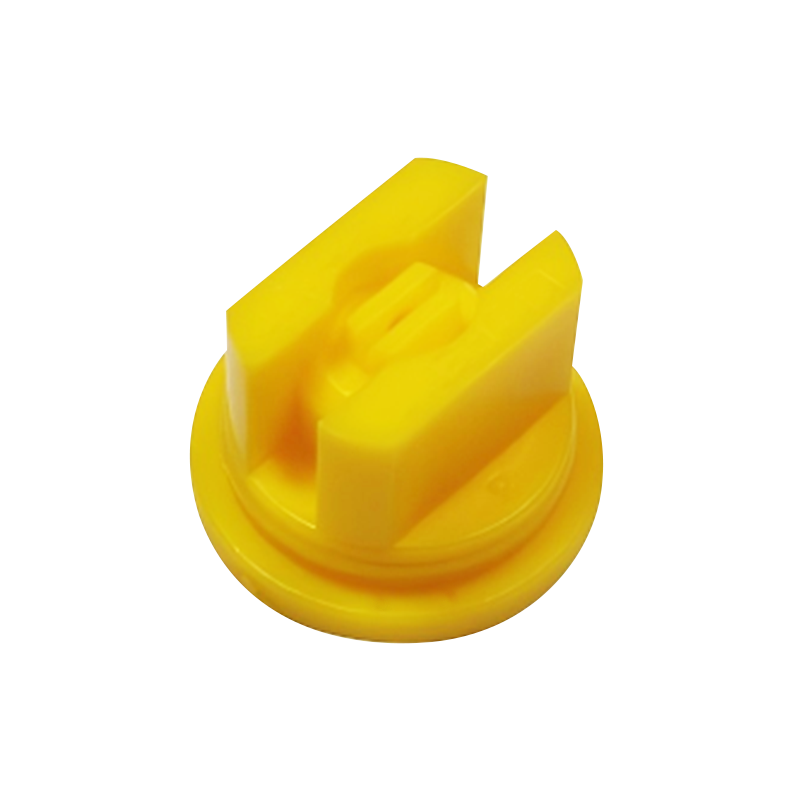

Different crops and pests require different spraying strategies—and high-quality nozzles offer flexible solutions. For instance, fan nozzles (producing wide, flat sprays) are ideal for large-area field crops like corn, while cone nozzles (delivering concentrated, circular sprays) work better for fruit trees or vegetables. The nozzle body, meanwhile, ensures easy replacement of nozzles, allowing farmers to switch between scenarios quickly without modifying the entire sprayer.

Extended Range Flat Spray Tip Nozzles: How Does Material Selection Influence Their Performance?

Extended range flat spray tip nozzles are widely used in agricultural spraying systems because they offer a broad operating pressure range, improved drift control, and consistent coverage. While their design, geometry, and flow characteristics are important, material selection is equally significant. The material used determines the nozzle’s durability, compatibility with chemicals, resistance to wear, and overall performance throughout the spraying season.

One commonly used material is plastic (polyacetal or polymer blends). Plastic nozzles are lightweight, cost-effective, and suitable for many routine spraying applications. Their resistance to various agricultural chemicals makes them a practical choice for general crop protection. However, they tend to wear more quickly than harder materials. For extended range designs—which operate under varying pressures—consistent orifice shape is important, and plastic material can gradually erode, affecting spray pattern accuracy.

Another material used is stainless steel, valued for its strength and resistance to abrasion. Stainless-steel extended range nozzles maintain their spray characteristics over longer periods, especially when applying fertilizers or abrasive crop protection mixtures. They also withstand frequent cleaning, making them ideal for heavy-duty use. However, stainless steel is typically more expensive and slightly heavier than plastic, which may influence equipment configurations that require many nozzles.

Ceramic is often regarded as the wear-resistant option. These nozzles can withstand extended use in abrasive environments, such as when applying suspensions or fertilizers containing particulates. Ceramic maintains its orifice shape exceptionally well, ensuring consistent performance over long periods. For extended range nozzles—especially those designed to maintain uniform patterns at both high and low pressures—material stability is beneficial. The main drawback is higher cost, but the extended life span often compensates for the initial investment.

Occasionally, brass is used, but its susceptibility to corrosion and relatively rapid wear limits its use in modern agricultural systems.

Selecting the right material depends on the type of chemicals used, expected operating pressures, maintenance practices, and budget. Farmers and applicators typically balance cost with durability, ensuring that extended range flat spray tip nozzles remain accurate and reliable throughout the season.

Sprayer Nozzles and Tips: What Types, Sizes, and Application Guidelines Should Users Follow?

Sprayer nozzles and tips are essential components that influence application rates, droplet size, spray distribution, and the effectiveness of agricultural chemical delivery. With a range of nozzle types and sizes available, selecting the right configuration requires an understanding of how each type functions and how application guidelines support consistent crop protection performance.

Several important nozzle types are commonly used. The flat fan nozzle produces a wide, even spray pattern, suitable for broadcast herbicide applications. Extended range versions allow operation across varied pressures, providing additional flexibility. Hollow cone nozzles generate fine, circular spray patterns ideal for insecticide and fungicide applications, especially when canopy penetration is required. Full cone nozzles deliver uniform coverage over a circular area, often used for soil-applied treatments or specific industrial applications. Air-induction nozzles, which mix liquid with air to produce coarser droplets, help reduce drift while still providing adequate coverage for many herbicides.

Nozzle sizes are indicated by standardized flow ratings—often color coded—to help users match nozzle output to application rates and operating pressures. Smaller-sized nozzles generate lower flow rates and finer droplets, while larger sizes produce higher flow rates and coarser droplets. Choosing the correct size requires aligning the nozzle flow rate with the sprayer’s operating pressure and the target application volume per hectare or acre. Manufacturers provide charts that specify flow and pressure relationships to simplify selection.

When considering application guidelines, several factors are important. Operating pressure must remain within the recommended range for each nozzle type. Excessively high pressure may produce overly fine droplets, increasing drift risk, while low pressure may uneven distribution. Second, nozzle height above the target surface affects spray uniformity. Flat fan nozzles, for example, require specific mounting heights to ensure proper overlap between spray patterns. Third, compatibility with chemical formulations matters. Some mixtures require specific droplet sizes to balance coverage and drift control, making nozzle type selection essential.

Routine inspection also supports proper application. Nozzles should be checked for wear, blockage, or changes in flow rate. A nozzle that delivers significantly more liquid than its rated output should be replaced to maintain application accuracy.

By selecting appropriate nozzle types, matching sizes to application needs, and following recommended operating guidelines, users can maintain reliable spray performance and support effective crop protection.

EN

EN  English

English 中文简体

中文简体 русский

русский