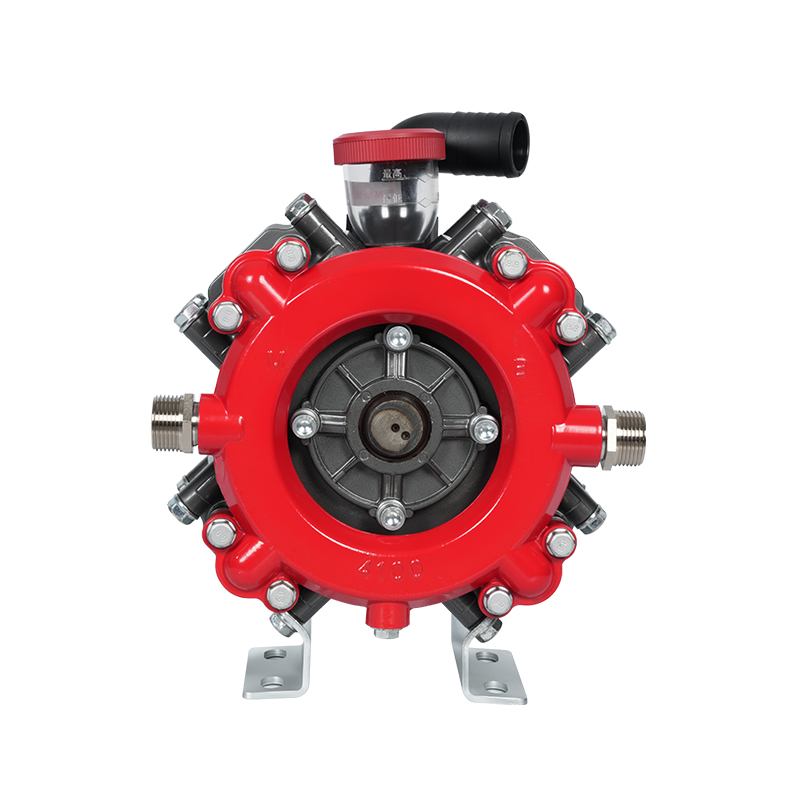

High pressure diaphragm pumps have become a cornerstone in modern agricultural and industrial spraying applications. Developed based on great international technology, this pump provides reliable operation under demanding conditions. Users frequently seek insights into efficiency, durability, and chemical compatibility when selecting a High Pressure Diaphragm Pump for Sprayers.

1. Efficiency in Operation

One of the main advantages is the combination of high operating pressure and stable discharge. These pumps can maintain consistent spray patterns even when multiple nozzles operate simultaneously. This capability reduces uneven coverage and ensures the liquid reaches the intended area effectively. Users also appreciate the self-priming feature, which simplifies setup, allowing pumps to draw liquid from tanks below the pump inlet without additional assistance.

2. Chemical Compatibility and Durability

A frequent concern is the pump's ability to handle a variety of chemicals without premature wear. The pump's components, including diaphragms, seals, and housing materials, are designed to resist corrosion and chemical attack. EPDM diaphragms are suitable for herbicides and fertilizers, while PTFE diaphragms handle more aggressive chemicals. By selecting the appropriate diaphragm and checking chemical compatibility, operators can extend service life and avoid unexpected failures.

3. Maintenance Considerations

Operators often ask how to reduce downtime and simplify maintenance. The High Pressure Diaphragm Pump for Sprayers separates hydraulic fluid from the chemical solution, protecting internal components. Worn items like diaphragms and valves can be replaced in the field with relative ease. Routine inspections, such as checking diaphragms, piston seals, and valves, help maintain steady performance and prevent heat buildup or reduced flow.

4. Versatility Across Applications

These pumps are designed for flexible deployment. They can be combined with electric motors, diesel engines, gasoline engines, tractors, or even automobiles to form different sprayer types. This makes them suitable for pest control in fields, orchards, forests, and urban gardens. Beyond agriculture, they support industrial tasks like vehicle cleaning, disinfection, and chemical infusion. Their compact design and high flow rate make them ideal for situations requiring precise pressure and coverage.

To choose the right model, users need to evaluate flow rate, pressure requirements, and the chemical types involved. The pump must supply the necessary volume for the sprayer system while maintaining stable pressure. Checking materials against the chemicals used and verifying the diaphragm type ensures long-term performance. Consultation with High Pressure Diaphragm Pump for Sprayers Manufacturers often provides additional guidance, particularly for specialized applications or challenging environments.

If a pump operates at high temperature or shows decreased performance, operators should check hydraulic fluid levels, inspect valves, and review system plumbing. Worn diaphragms or seals can reduce efficiency and generate heat. Addressing these issues promptly prevents damage and prolongs the pump's life. Following manufacturer recommendations from High Pressure Diaphragm Pump For Sprayers Manufacturers ensures that both field and industrial applications continue smoothly.

The High Pressure Diaphragm Pump for Sprayers is engineered for durability, chemical resistance, and operational flexibility. With proper selection, maintenance, and operational awareness, it serves a wide range of agricultural and industrial spraying needs. By understanding pressure, flow, and material compatibility, operators can make informed decisions and maintain reliable, efficient spray performance.

EN

EN  English

English 中文简体

中文简体 русский

русский