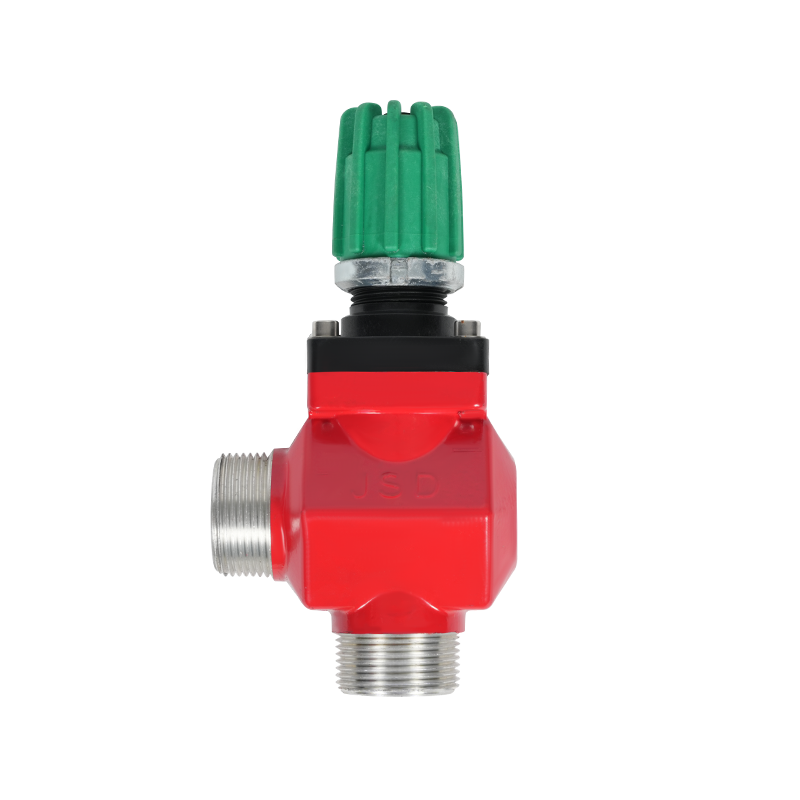

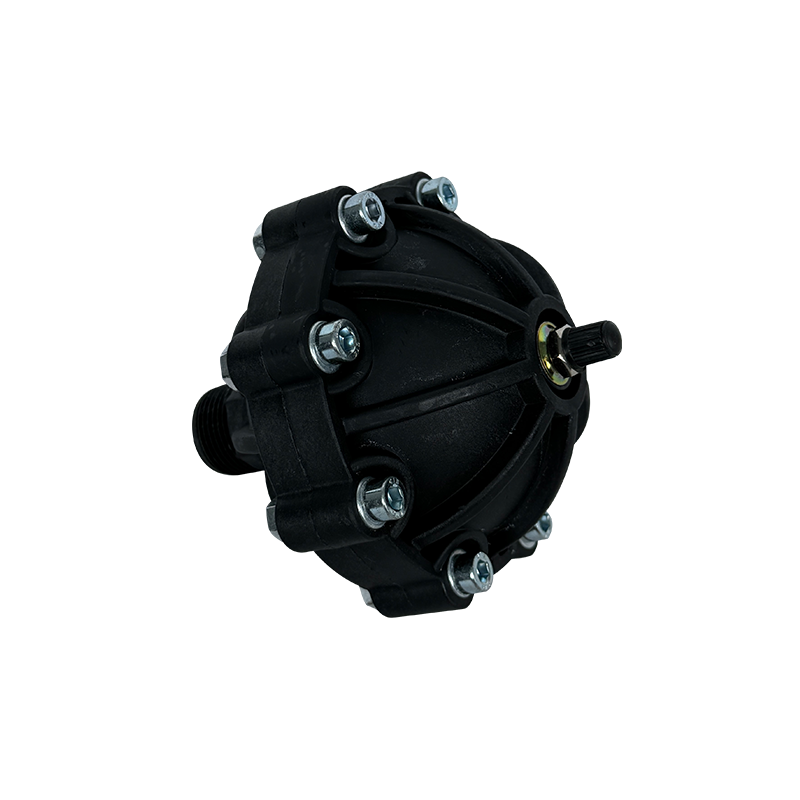

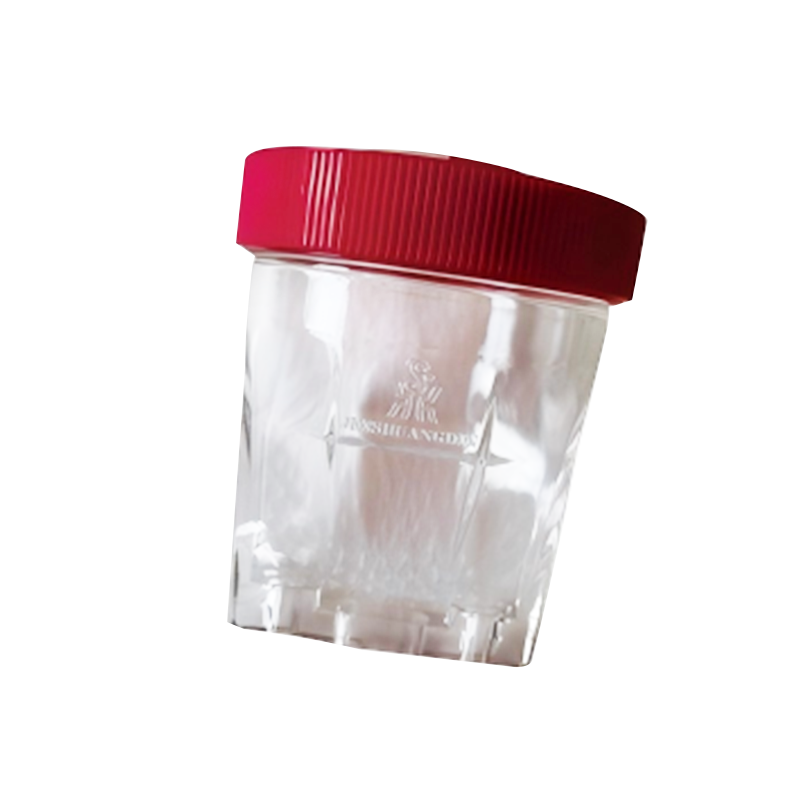

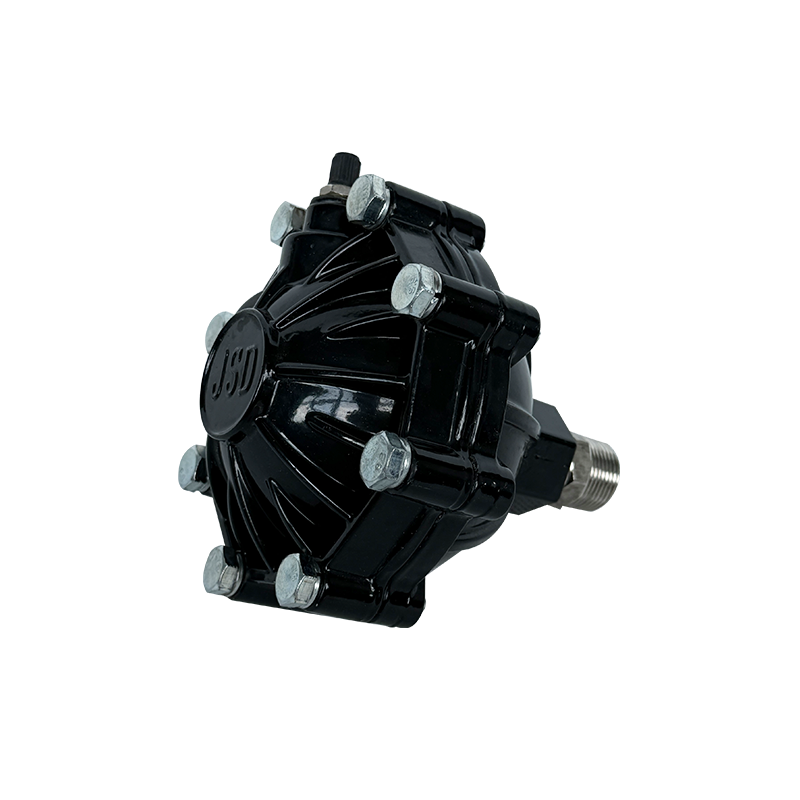

Diaphragm pump accessories mainly include the diaphragm, inlet and outlet valves, pump body, cylinder head, outlet cover, inlet and outlet flow channels, piston, connecting rod, pump shaft, oil seal, pressure regulating valve, inlet and outlet joints, sealing rings, etc. Each component ensures efficient fluid transportation, prevents leakage, and prolongs the service life of the pump, allowing it to operate reliably in various industrial applications.

-

0m²

0m²Manufacturing Base

-

0+

0+Patented Technologies

Jinhua Shuangding Machinery Co., Ltd. is a Wholesale Diaphragm Pump Accessories Manufacturer and China Diaphragm Pump Accessories Factory, specializing in the development Manufacture and sales of the brand "SHANG DING", "JIN SHUANG DING", "A-FARMERY" series of PTO diaphragm pumps, spray nozzles, spray pipes, control regulators that match different power equipment (such as electric motor, diesel engine, gasoline engine, tractor, and motor vehicle, etc) to form various models of sprayer.

Since our establishment, we have devoted ourselves to developing various PTO diaphragm pumps, spray nozzle sets, filters, and control regulators. Based on advanced technology and scientific management, a modern production line, complete test equipment, and a quality control system, our product quality improves.

-

Feb 24,2026

What Are Common Issues in a Diaphragm Pump For Pesticides System?

Modern agricultural spraying relies on stable pressure, predictable flow, and reliable chemical handling. A Diaphragm Pump For Pesticides fits these needs b...

-

Feb 20,2026

How Does a Crop Spraying Diaphragm Pump Perform Under Dry Running?

Crop protection spraying is not only about moving liquid from a tank to a nozzle. In real field work, operators deal with chemical corrosion, unstable press...

-

Feb 13,2026

How Does an Agricultural Sprayer Pump Handle Multiple Nozzles?

An Agricultural Sprayer Pump is not just a supporting component in spraying equipment. It directly influences application accuracy, spray stability, and che...

-

Feb 06,2026

How Does a Sprayer Diaphragm Pump Support Long Hose Spraying?

A Sprayer Diaphragm Pump is a core component in many power sprayers used for garden, agricultural, and landscape applications. Its role is not just to move ...

What are some common diaphragm pump parts and accessories, and what are their functions?

The core of the pump is the diaphragm, a flexible membrane that moves back and forth, creating a pumping action. It isolates the pumped fluid from the hydraulic oil, protecting the pump's mechanics from corrosive or abrasive chemicals. Valves are equally critical; pumps employ ball valves, consisting of a ball, seat, and cage. These one-way valves open and close with each diaphragm stroke, controlling the flow of liquid into (inlet valve) and out of (outlet valve) the pumping chamber, preventing backflow. The housing or pump head is the main structural component that contains the fluid path and holds the valves and diaphragm in place.

Several accessories enhance functionality. Pulse dampeners are vessels installed on the discharge side that contain a pressurized air bladder or diaphragm. They absorb the pressure pulses inherent to the reciprocating action of the pump, resulting in a smoother fluid flow and reducing stress on the entire sprayer system. Pressure regulators allow the operator to precisely set and maintain the desired system pressure, which is essential for consistent nozzle output and accurate chemical application. Finally, pressure gauges provide a visual confirmation of the system pressure, enabling operators to monitor pump performance and ensure the sprayer is operating within its intended parameters.

What is typically included in a standard repair kit?

A standard repair kit is designed for routine preventative maintenance and usually contains the common wear components. This typically includes a set of diaphragms, the corresponding gaskets and O-rings, and a full set of inlet and outlet valve assemblies (balls, seats, and cages). Some comprehensive kits may also include the piston seal for piston-diaphragm pump models.

When should I use a repair kit versus ordering individual parts?

Using a repair kit is generally advised for scheduled maintenance or when multiple components are nearing the end of their service life. It is a cost-effective and efficient approach to ensure all interdependent wear parts are replaced simultaneously, preventing a premature failure of one new part due to an old, worn companion. Order individual parts when a specific, identified component has failed and the other parts are known to be in good condition.

Are there different kits for different pump models?

Yes, repair kits are model-specific. Components like diaphragm size, valve dimensions, and seal types vary significantly between pump manufacturers and even within a manufacturer's different series. It is essential to know your pump's exact model number to order the correct kit, as using an incompatible kit can pump damage and poor performance.

How often should I replace the diaphragms and valves?

Replacement intervals are not fixed and depend heavily on usage hours, the types of chemicals pumped, and operating pressures. A common recommendation is to inspect these components annually and replace them as part of a preventative maintenance schedule. However, a noticeable drop in pressure, irregular pump pulsation, or visible damage to any component are clear indicators that immediate replacement is necessary.

How to Troubleshoot a Diaphragm Pump That Has Lost Pressure?

Check for Suction and Discharge Issues

- Inspect inlet strainer and lines: A clogged suction strainer or a collapsed, kinked, or air-leaking inlet hose can starve the pump of fluid, causing cavitation and a pressure drop.

- Examine the discharge side: Check for leaks in hoses, fittings, or the pressure regulator. A faulty open bypass valve or a stuck-open nozzle can also divert flow, preventing pressure buildup.

Inspect Internal Wear Components

- Diaphragms: Worn, torn, or permanently deformed diaphragms lose their ability to create an effective pumping chamber, a significant loss of displacement and pressure.

- Valves: Worn valve balls and seats will not seal properly, allowing fluid to slip back into the pump chamber or to the tank. Debris holding a valve open will have the same effect.

- Piston Seal: In piston-diaphragm pumps, a worn piston seal allows hydraulic oil to bypass, reducing the stroke length and force transferred to the diaphragm.

Evaluate the Hydraulic and Drive Systems

- Hydraulic oil level and condition: Low oil level is a primary cause of pressure loss, as it results in an incomplete diaphragm stroke. Contaminated or degraded oil can also affect performance.

- Drive system integrity: For mechanically driven pumps, a worn gear, loose belt, or a failing clutch can prevent the pump from achieving its required operating speed, reduced pressure.

EN

EN  English

English 中文简体

中文简体 русский

русский