Filters are an essential component in agricultural spraying systems and are known as the "guardians" of the spray solution. Their primary function is to filter impurities from the spray solution, prevent nozzle clogging, and ensure smooth, uniform, and efficient spraying operations.

-

0m²

0m²Manufacturing Base

-

0+

0+Patented Technologies

Jinhua Shuangding Machinery Co., Ltd. is a Wholesale Inlet And Outlet Water Filters Manufacturer and China Inlet And Outlet Water Filters Factory, specializing in the development Manufacture and sales of the brand "SHANG DING", "JIN SHUANG DING", "A-FARMERY" series of PTO diaphragm pumps, spray nozzles, spray pipes, control regulators that match different power equipment (such as electric motor, diesel engine, gasoline engine, tractor, and motor vehicle, etc) to form various models of sprayer.

Since our establishment, we have devoted ourselves to developing various PTO diaphragm pumps, spray nozzle sets, filters, and control regulators. Based on advanced technology and scientific management, a modern production line, complete test equipment, and a quality control system, our product quality improves.

-

Feb 24,2026

What Are Common Issues in a Diaphragm Pump For Pesticides System?

Modern agricultural spraying relies on stable pressure, predictable flow, and reliable chemical handling. A Diaphragm Pump For Pesticides fits these needs b...

-

Feb 20,2026

How Does a Crop Spraying Diaphragm Pump Perform Under Dry Running?

Crop protection spraying is not only about moving liquid from a tank to a nozzle. In real field work, operators deal with chemical corrosion, unstable press...

-

Feb 13,2026

How Does an Agricultural Sprayer Pump Handle Multiple Nozzles?

An Agricultural Sprayer Pump is not just a supporting component in spraying equipment. It directly influences application accuracy, spray stability, and che...

-

Feb 06,2026

How Does a Sprayer Diaphragm Pump Support Long Hose Spraying?

A Sprayer Diaphragm Pump is a core component in many power sprayers used for garden, agricultural, and landscape applications. Its role is not just to move ...

How Do Key Agricultural Water Flow Components Function and When Should They Be Replaced?

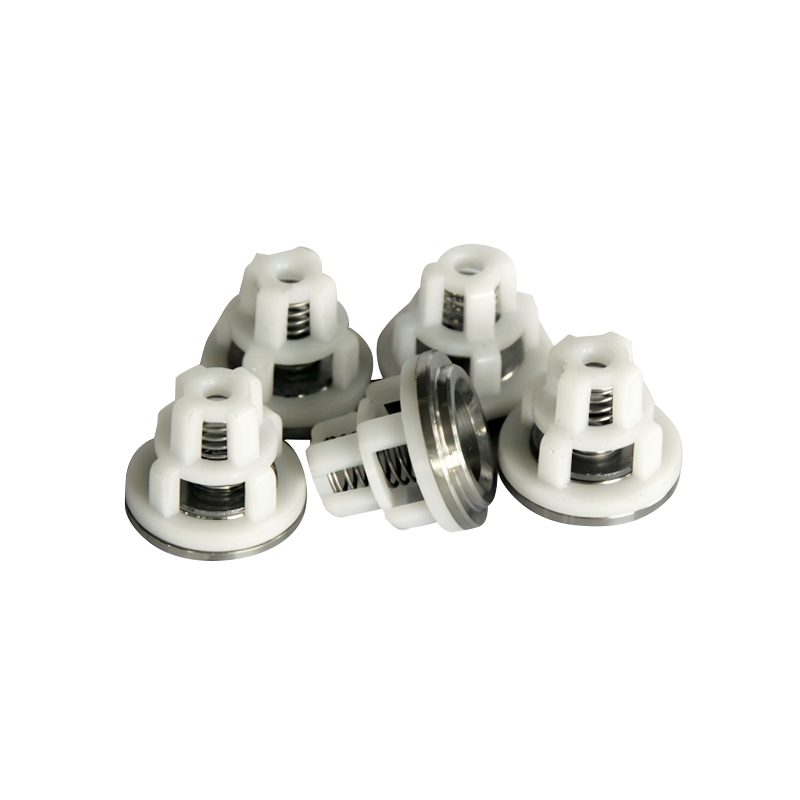

The Function of Inlet and Outlet Water Filters

Inlet and outlet water filters play an important role in maintaining the performance and longevity of agricultural spraying systems. These filters keep contaminants from entering sensitive components, ensuring that pumps, valves, and nozzles operate smoothly. Their function is both protective and preventive, helping to maintain consistent spray quality and reducing unexpected downtime during field operations.

Main Functions of Inlet Water Filters

- Prevent debris from entering the pump

Inlet filters catch suspended particles, leaves, soil, and other contaminants before they reach the pump chamber. This helps avoid internal wear and unexpected blockages.

- Support stable water flow

By keeping incoming water clean, inlet filters reduce fluctuations in flow and pressure. This supports uniform spraying and predictable equipment performance.

- Reduce pump maintenance

Cleaner incoming water reduces abrasion and chemical buildup on internal pump surfaces, lowering the frequency of repairs.

Main Functions of Outlet Water Filters

- Protect spray nozzles from clogging

Outlet filters ensure that fine particles do not reach the nozzle tips, which are often designed with narrow openings for precision spraying.

- Improve spray pattern consistency

By supplying clean, particle-free liquid, outlet filters help maintain the intended spray distribution and droplet size.

- Support chemical application efficiency

When spray patterns remain consistent, chemicals are applied evenly, contributing to efficient use of spray materials.

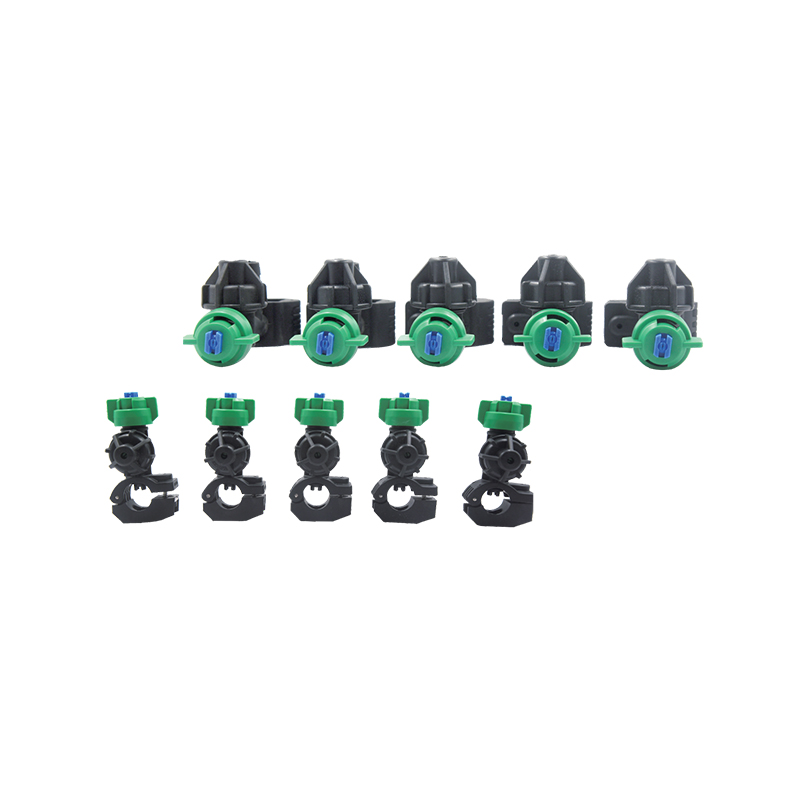

How Often Does the Agricultural Water Spray Assembly Need to Be Replaced?

The agricultural water spray assembly includes hoses, connectors, nozzles, and fittings that work together to deliver liquid to crops. Its lifespan depends on operating conditions, water quality, and frequency of use. Replacement is necessary when performance begins to decline or when visible wear becomes significant. The following three subheadings explain common factors that influence replacement timing.

1. Wear Caused by Chemical Exposure

- Many crop protection products contain active ingredients that gradually wear down rubber and plastic components.

- Repeated exposure can cause hoses and gaskets to stiffen, crack, or lose flexibility.

- Assemblies used with highly acidic or alkaline solutions typically require more frequent replacement.

- If chemical residue causes buildup on internal surfaces, spray patterns may become uneven, indicating it is time for replacement.

2. Mechanical Stress and Field Conditions

- Spray assemblies frequently operate in outdoor environments where heat, sunlight, and movement place stress on components.

- UV exposure can weaken hose materials, brittleness.

- Abrasion from repeated dragging or contact with rough surfaces may cause thinning or punctures.

- Operators should replace the assembly when visible damage, frequent leakage, or reduced pressure becomes noticeable.

3. Performance Decline and Aging

- Even when used under controlled conditions, spray assemblies naturally age over time.

- Internal surfaces may accumulate scale or sediment, slowly reducing flow efficiency.

- O-rings and seals lose elasticity after long-term use, causing small leaks that reduce system pressure.

- Replacement should be considered when cleaning and routine maintenance no longer restore normal performance.

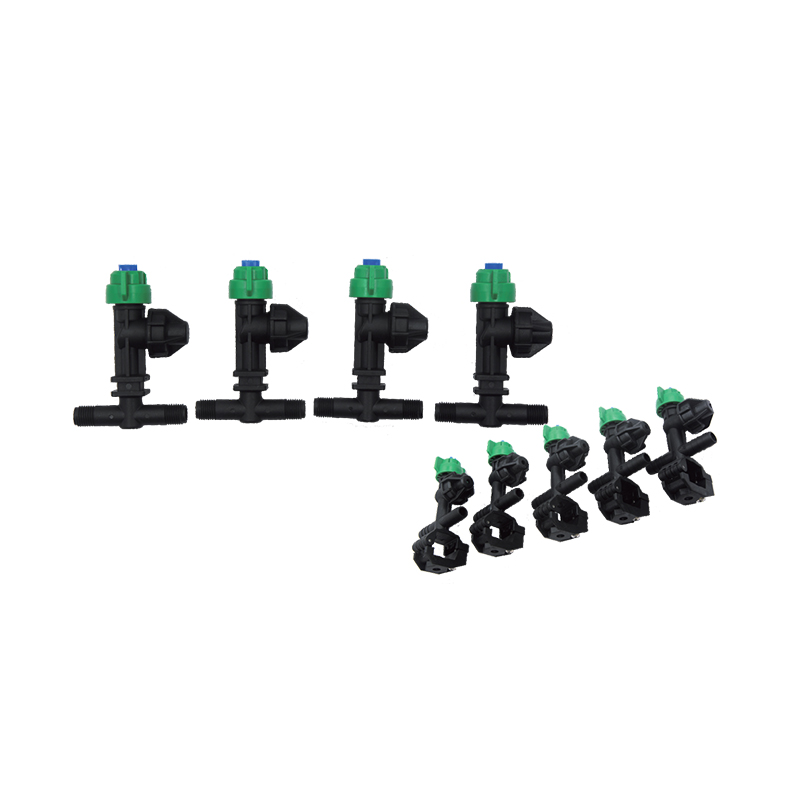

What is a Split Pressure Regulator Assembly?

A split pressure regulator assembly is a control component used in agricultural sprayers to maintain consistent pressure across different spray lines. It divides the incoming pressure into two or more controlled outputs. This design allows operators to regulate multiple sections of the sprayer independently, improving accuracy and flexibility during field operation.

Why Is a Split Pressure Regulator Important for Spraying Applications?

The assembly ensures that each spray section receives the correct amount of pressure, which is essential for uniform distribution of chemicals. Without balanced pressure, some sections may deliver too much or too little spray. A split regulator prevents uneven coverage, supports efficient chemical use, and contributes to predictable spray patterns, especially when using boom sprayers with multiple nozzles.

How Should the Split Pressure Regulator Be Maintained?

Maintenance includes regularly checking the regulator diaphragm for wear, cleaning sediment from internal chambers, and inspecting adjustment knobs for smooth operation. Operators should also verify that pressure gauges respond accurately and that hoses connected to the regulator are free from cracks. Proper maintenance improves reliability and reduces the likelihood of fluctuations in spray performance. If consistent pressure becomes difficult to achieve even after cleaning, the regulator may need replacement.

EN

EN  English

English 中文简体

中文简体 русский

русский