-

0m²

0m²Manufacturing Base

-

0+

0+Patented Technologies

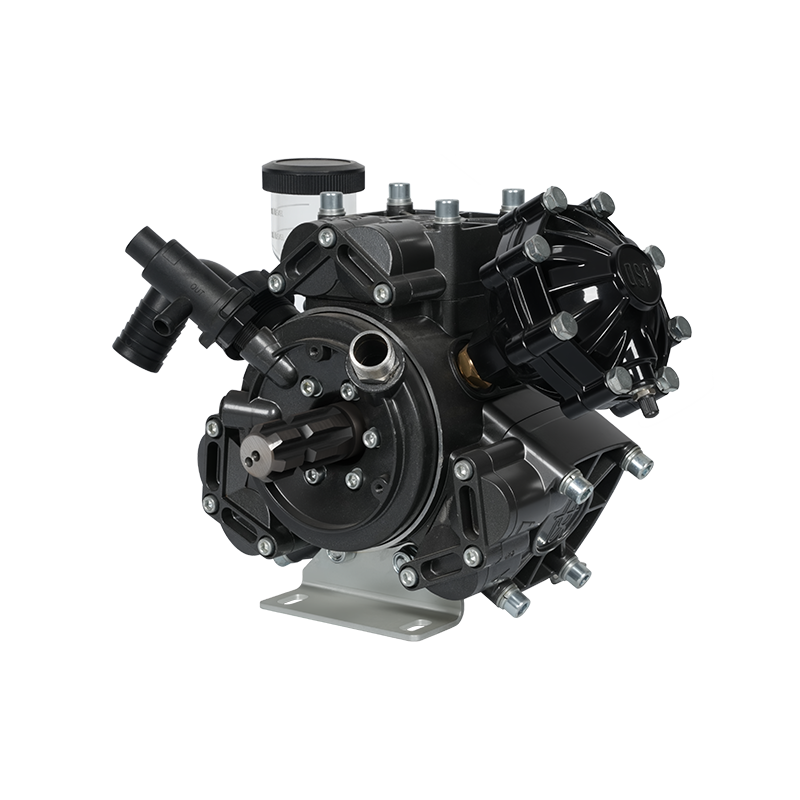

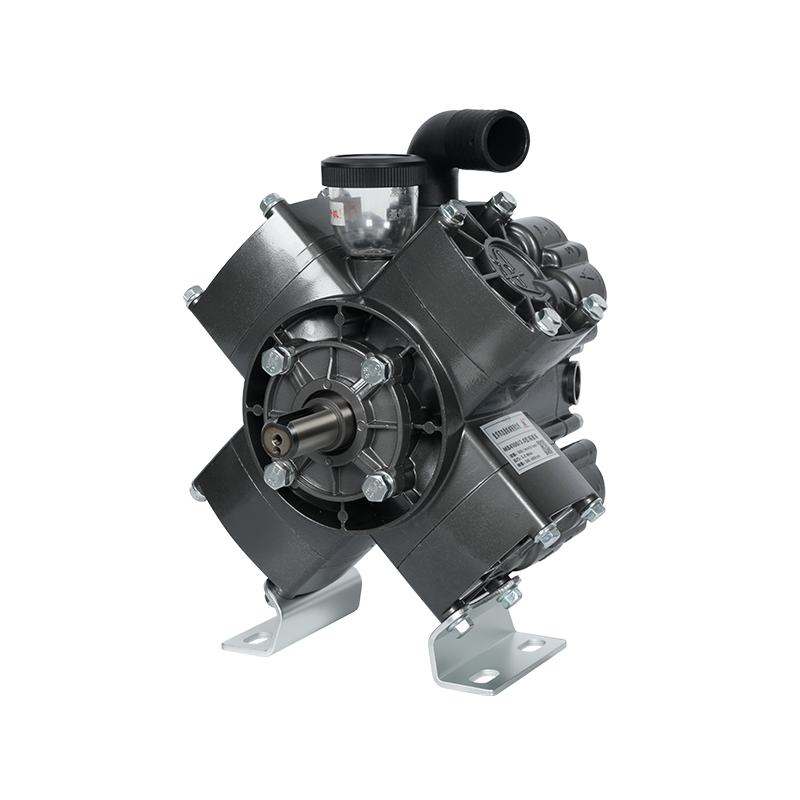

Jinhua Shuangding Machinery Co., Ltd. is a Crop Spraying Diaphragm Pump Supplier and Electric Diaphragm Pump Factory, specializing in the development Manufacture and sales of the brand "SHANG DING", "JIN SHUANG DING", "A-FARMERY" series of PTO diaphragm pumps, spray nozzles, spray pipes, control regulators that match different power equipment (such as electric motor, diesel engine, gasoline engine, tractor, and motor vehicle, etc) to form various models of sprayer.

Since our establishment, we have devoted ourselves to developing various PTO diaphragm pumps, spray nozzle sets, filters, and control regulators. Based on advanced technology and scientific management, a modern production line, complete test equipment, and a quality control system, our product quality improves.

-

Feb 24,2026

What Are Common Issues in a Diaphragm Pump For Pesticides System?

Modern agricultural spraying relies on stable pressure, predictable flow, and reliable chemical handling. A Diaphragm Pump For Pesticides fits these needs b...

-

Feb 20,2026

How Does a Crop Spraying Diaphragm Pump Perform Under Dry Running?

Crop protection spraying is not only about moving liquid from a tank to a nozzle. In real field work, operators deal with chemical corrosion, unstable press...

-

Feb 13,2026

How Does an Agricultural Sprayer Pump Handle Multiple Nozzles?

An Agricultural Sprayer Pump is not just a supporting component in spraying equipment. It directly influences application accuracy, spray stability, and che...

-

Feb 06,2026

How Does a Sprayer Diaphragm Pump Support Long Hose Spraying?

A Sprayer Diaphragm Pump is a core component in many power sprayers used for garden, agricultural, and landscape applications. Its role is not just to move ...

How Do Crop Spraying Diaphragm Pumps Work and Why Are They Essential?

Crop spraying diaphragm pumps play a central role in modern agricultural operations, particularly in precision application of pesticides, herbicides, and liquid fertilizers. Their operation is based on a simple but effective mechanism: a flexible diaphragm moves back and forth to create suction and discharge cycles. This movement draws liquid into the pump chamber on one stroke and pushes it out through the outlet on the next. Because the liquid never contacts the mechanical parts directly, these pumps provide strong chemical compatibility and long service life. Their controlled pulsation and steady flow make them suitable for both small-scale spraying equipment and professional agricultural sprayers.

One of the reasons these pumps are essential is their ability to handle a wide range of fluid viscosities while maintaining consistent pressure. Farmers rely on them for uniform spray coverage, which contributes to responsible chemical usage and supports better crop outcomes. Diaphragm pumps also tolerate abrasive chemicals and suspended particles, reducing the risk of operational downtime. Additionally, they are valued for their relatively low maintenance needs and energy efficiency, which contribute to predictable performance in demanding field conditions.

Features and Functions of Crop Spraying Diaphragm Pumps

|

Feature |

Description |

|

Pumping Mechanism |

A diaphragm moves to create suction and discharge without liquid contacting internal moving parts. |

|

Chemical Compatibility |

Suitable for various chemicals, including corrosive and abrasive solutions. |

|

Flow Stability |

Provides steady, pulseless flow suitable for precision spraying. |

|

Durability |

Resistant to wear due to indirect contact between fluid and mechanical components. |

|

Applications |

Used in agricultural sprayers, orchard equipment, and fertilizer applicators. |

What Are the Different Types of Electric Diaphragm Pumps?

Electric diaphragm pumps are widely used in agriculture, cleaning systems, fluid transfer, and light industrial applications. They operate using an electric motor that drives a diaphragm or multiple diaphragms, providing dependable flow without the need for combustion engines. Several types are available, each offering benefits tailored to specific tasks.

The single-diaphragm electric pump is one of the common models. It is compact, lightweight, and suitable for low-to-medium flow applications such as portable sprayers and small-scale irrigation systems. Its straightforward construction makes it cost-effective while still offering the chemical resistance typical of diaphragm pumps.

Double-diaphragm electric pumps provide higher flow capacities and improved pressure stability. Their dual-chamber design allows continuous delivery with reduced pulsation, making them suitable for applications requiring consistent spraying or dosing. These pumps are commonly used in medium-sized agricultural equipment and industrial cleaning systems.

A more specialized category includes variable-speed electric diaphragm pumps, which incorporate electronic control systems. These allow precise adjustment of flow and pressure, supporting operations where accurate dosing of liquids is important. Users can calibrate output to match specific spray patterns or chemical requirements, improving resource efficiency.

High-pressure electric diaphragm pumps are designed for demanding applications where stronger force is needed, such as orchard spraying or long hose runs. Their enhanced construction ensures stable performance even under elevated pressures.

These types of electric diaphragm pumps offer versatility, energy efficiency, and reliable performance across a wide range of spraying and fluid-handling needs.

What Are the Advantages of Engine-Driven Diaphragm Pumps?

Engine-driven diaphragm pumps are valued for their independence from electrical power sources and their strong operational capabilities. Below are three key advantages, each explained under a dedicated subheading.

Reliable Power for Remote or Large-Scale Operations

This makes them well-suited for large fields, orchard environments, and remote areas where electricity is unavailable. The combustion engine provides steady mechanical power, ensuring consistent pressure and flow even during prolonged operation. As a result, farmers can complete extended spraying tasks without interruption, contributing to productivity and efficient field management.

Strong Performance With High Flow and Pressure Needs

Engine-driven models are built to handle heavy-duty spraying and fluid transfer applications. The robust engine allows the pump to produce higher pressures and flow rates compared to smaller electric counterparts. This capability is especially useful for high-coverage spraying, tree spraying in orchards, or operations requiring long-distance liquid delivery. Their stability under demanding conditions helps maintain uniform distribution of chemicals, which supports precise and efficient agricultural practices.

Durable Construction Suitable for Demanding Environments

Engine-driven diaphragm pumps are designed with reinforced components that withstand constant vibration, temperature variations, and prolonged mechanical loads. Because the diaphragm isolates the fluid from internal moving parts, the pump remains resistant to chemical corrosion and abrasive materials. This design lowers maintenance frequency and supports long-term reliability. For users who require equipment capable of performing under tough field conditions, these pumps offer a balanced combination of strength and longevity.

EN

EN  English

English 中文简体

中文简体 русский

русский