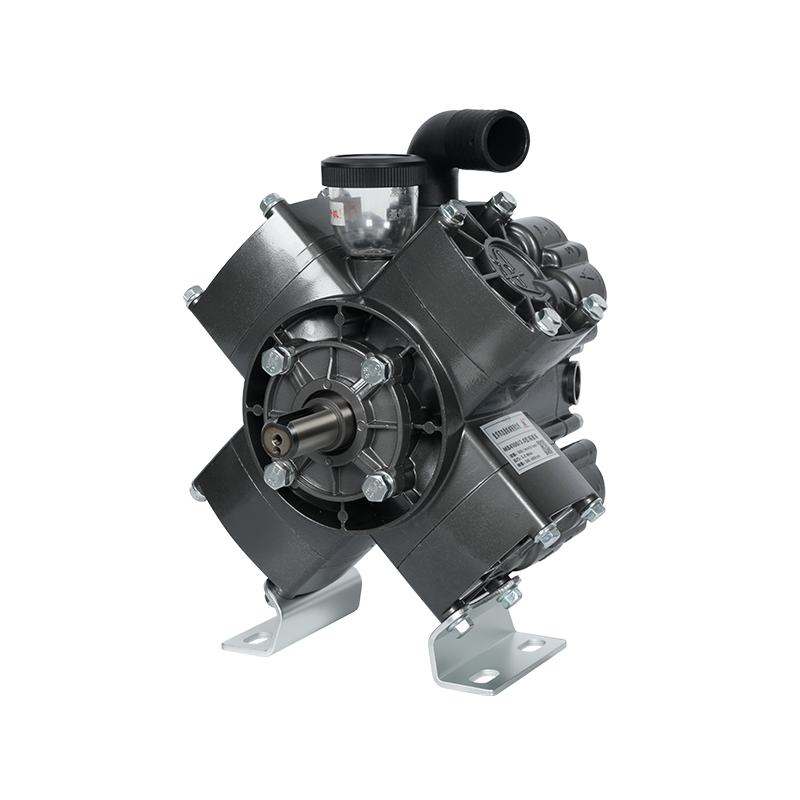

An Agricultural Sprayer Pump provides consistent pressure and flow, which ensures uniform application of fertilizers, herbicides, and pesticides across different crops. Consistent pressure prevents missed spots and reduces over-application, saving both time and chemical costs. These pumps are designed with high flow rates and stable discharge pressure, making them suitable for a wide range of field sizes, from small orchards to large paddy fields and forests.

The compact and rational structure of modern pumps allows them to be mounted on various sprayers and misters, whether powered by electric motors, diesel or gasoline engines, tractors, or automobiles. Their flexibility enables operators to handle both flat and hilly terrains effectively. With precise spraying, the pump supports multiple nozzle configurations, helping maintain even droplet size and spray patterns. This efficiency not only improves crop protection but also enhances the overall productivity of farm operations.

1. Durable Design and Chemical Compatibility

Durability is a key factor in choosing an Agricultural Sprayer Pump. Great pumps are built with corrosion-resistant materials such as polypropylene for the housing and EPDM or PTFE for diaphragms. These materials can handle a wide range of agricultural chemicals, including concentrated fertilizers, herbicides, and insecticides, without rapid wear.

Diaphragm-based designs are particularly advantageous because they can tolerate short periods of dry running, which commonly occur during tank refills or temporary blockages in suction lines. This capability reduces the risk of damage compared to centrifugal pumps. Choosing the right diaphragm material is essential: EPDM diaphragms provide reliable performance for general chemicals, while PTFE diaphragms are better suited for aggressive chemicals and solvents.

Reputable Agricultural Sprayer Pump Manufacturers offer detailed guidance on chemical compatibility and material selection. This ensures the pump operates efficiently and extends its service life, reducing unexpected maintenance costs and downtime. Manufacturers also provide charts and technical specifications, helping users make informed decisions for specific agricultural applications.

2. Maintenance, Flow Rate, and Pressure Management

Maintaining an Agricultural Sprayer Pump is straightforward but essential for long-term reliability. Regular inspection of diaphragms and valves is critical, as worn components can reduce efficiency and increase the risk of overheating. Checking hydraulic fluid levels and condition prevents internal damage and ensures smooth operation. Cleaning suction and discharge lines avoids clogs that can cause uneven spraying and pressure drops.

Flow rate and pressure directly affect spraying performance. Operators should calculate the required flow based on boom width, travel speed, and nozzle output. Maintaining consistent pressure, usually between 40 and 150 PSI, ensures even chemical application and avoids wasted resources. Selecting a pump slightly above the calculated requirements allows for wear over time while maintaining performance. Proper maintenance also helps prevent overheating, which may result from low hydraulic fluid, worn valves, or restricted flow paths.

Agricultural Sprayer Pump Manufacturers provide guidance on installation, operation, and spare parts. Their support ensures that pumps are correctly installed, maintained, and repaired when necessary. Field technicians can easily replace diaphragms, valves, or seals, reducing downtime and maintaining efficiency. Access to professional advice helps operators avoid common mistakes, achieve good spraying performance, and extend the lifespan of their equipment. Choosing a manufacturer that offers both quality products and technical support is crucial for long-term success in both farming and industrial applications.

EN

EN  English

English 中文简体

中文简体 русский

русский