The nozzle, through its sophisticated internal structure, breaks the high-pressure pesticide solution into countless fine droplets. The nozzle, which supports and secures the nozzle, is responsible for delivering the pesticide solution to each nozzle. Together, the nozzle and nozzle constitute the sprayer's "terminal execution system," directly determining the atomization quality, distribution, and spraying accuracy of the pesticide solution. These factors are crucial for pesticide utilization and pest control effectiveness.

-

0m²

0m²Manufacturing Base

-

0+

0+Patented Technologies

Jinhua Shuangding Machinery Co., Ltd. is a Wholesale Nozzles Manufacturer and China Nozzles Factory, specializing in the development Manufacture and sales of the brand "SHANG DING", "JIN SHUANG DING", "A-FARMERY" series of PTO diaphragm pumps, spray nozzles, spray pipes, control regulators that match different power equipment (such as electric motor, diesel engine, gasoline engine, tractor, and motor vehicle, etc) to form various models of sprayer.

Since our establishment, we have devoted ourselves to developing various PTO diaphragm pumps, spray nozzle sets, filters, and control regulators. Based on advanced technology and scientific management, a modern production line, complete test equipment, and a quality control system, our product quality improves.

-

Feb 24,2026

What Are Common Issues in a Diaphragm Pump For Pesticides System?

Modern agricultural spraying relies on stable pressure, predictable flow, and reliable chemical handling. A Diaphragm Pump For Pesticides fits these needs b...

-

Feb 20,2026

How Does a Crop Spraying Diaphragm Pump Perform Under Dry Running?

Crop protection spraying is not only about moving liquid from a tank to a nozzle. In real field work, operators deal with chemical corrosion, unstable press...

-

Feb 13,2026

How Does an Agricultural Sprayer Pump Handle Multiple Nozzles?

An Agricultural Sprayer Pump is not just a supporting component in spraying equipment. It directly influences application accuracy, spray stability, and che...

-

Feb 06,2026

How Does a Sprayer Diaphragm Pump Support Long Hose Spraying?

A Sprayer Diaphragm Pump is a core component in many power sprayers used for garden, agricultural, and landscape applications. Its role is not just to move ...

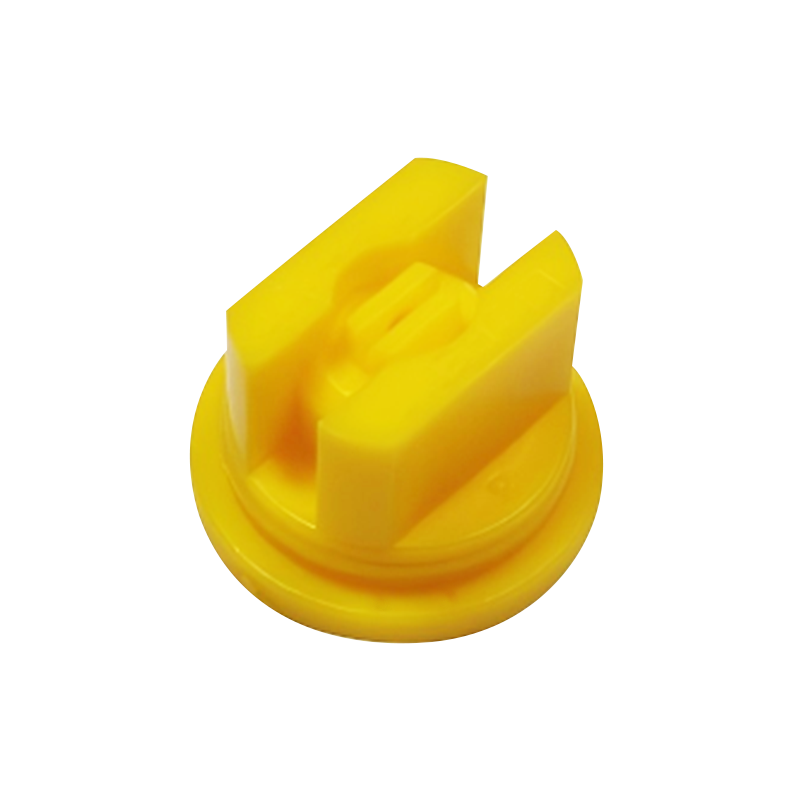

The Manufacturing Process of Standard Flat Fan Spray Tips

Standard flat fan spray tips are widely used components in agricultural sprayers, and their manufacturing process involves several controlled steps to ensure accuracy and durability. The process begins with material selection, typically involving stainless steel, brass, ceramic, or high-grade polymers. Each material offers different levels of resistance to wear and chemical corrosion, so manufacturers choose based on the intended application and expected nozzle lifespan.

Once the material is selected, the next stage is precision forming. For metal tips, this may involve forging, machining, or laser cutting to shape the nozzle body. Ceramic models are typically molded and fired in a kiln to achieve both hardness and stability. Polymer nozzles are produced using injection molding, where molten plastic is formed into the desired shape using high-precision molds.

After shaping, the critical orifice geometry is fabricated. This small opening controls the spray pattern, droplet size, and flow rate, so its accuracy is essential. Advanced machining tools, lasers, or micro-molding techniques are used to maintain consistent dimensions across large production volumes.

Each tip undergoes quality inspection, which may include flow testing, visual inspection, and pattern verification. Manufacturers often use automated systems to check whether the spray angle and distribution match required standards.

The nozzles are finished, cleaned, and packaged. Some may receive coatings or surface treatments to enhance longevity. By maintaining tight control over material selection, forming, machining, and testing, manufacturers ensure that standard flat fan spray tips perform consistently in agricultural and industrial applications.

How Often Do Agricultural Sprayer Nozzles Need to Be Replaced?

Agricultural sprayer nozzles require periodic replacement to maintain accurate application rates and consistent spray patterns. The exact replacement frequency depends on factors such as material type, operating conditions, chemical exposure, and total usage hours.

Nozzles made from softer materials, such as plastic or brass, tend to wear more quickly. They may require replacement after one or two spraying seasons, especially if they are used frequently or with abrasive materials. In contrast, ceramic and stainless-steel nozzles last longer because they resist wear from high-pressure flow and chemical exposure. Even so, they should still be inspected regularly.

Signs that nozzles need replacement include uneven spray patterns, reduced pressure, increased flow rate, or streaking in the field. A worn nozzle often delivers more liquid than intended, which may inconsistent application. Checking nozzles at the start of each season is recommended, and many operators conduct mid-season inspections during high-use periods.

Comparing the actual output of a nozzle to its rated flow is another reliable way to determine wear. If the nozzle outputs more than about five to ten percent above the specified rate, replacement is usually recommended. Using clean water and filters can slow the wear process, but regular cleaning alone cannot restore worn nozzle surfaces.

Agricultural sprayer nozzles should be replaced annually for medium to heavy use, while more durable materials may last several seasons under lighter conditions. Maintaining a consistent replacement schedule ensures accurate application rates, dependable coverage, and overall sprayer efficiency.

Where Are Flat Fan Spray Tips Commonly Used?

Flat fan spray tips are valued for their ability to produce a uniform, sheet-like spray pattern, making them suitable for a variety of agricultural and non-agricultural applications. Their common use is in field crop spraying, where they apply herbicides, pesticides, and foliar nutrients. The even distribution created by a flat fan pattern helps maintain consistent application rates across boom widths, supporting predictable crop performance.

They are also widely used for pre-emergent and post-emergent herbicide applications. The narrow, controlled spray angle helps operators target specific rows or sections of the field. Many growers rely on flat fan tips for broadcast spraying when uniform coverage is needed over wide areas.

Outside of crop spraying, these tips are used in orchard and vineyard systems, especially when mounted on sprayers designed to cover foliage at varying heights. In these settings, different spray angles help direct liquid toward the canopy and lower foliage effectively.

In industrial environments, flat fan spray tips are used for cleaning, cooling, and coating tasks. Their controlled distribution makes them suitable for conveyor belt washing, surface preparation, dust control, and applying thin coatings to surfaces.

They are also common in lawn and turf management, including parks, golf courses, and landscape maintenance. Their ability to deliver fine, even droplets makes them appropriate for applying liquid fertilizers and selective herbicides across large grassy areas.

EN

EN  English

English 中文简体

中文简体 русский

русский